一週間を要するが、酵素精練では8時間で十分である。

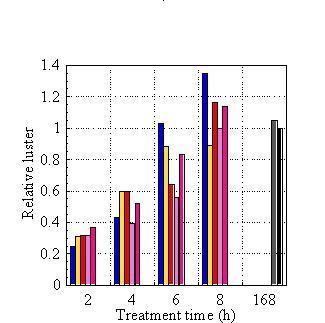

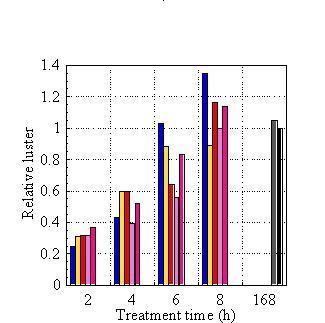

Relative luster of kudzu fibers retted with enzymes.

Incident beam angle was set at 15°from horizontal and

regular reflection was measured along to the fiber axis.

■viscozyme L,

■ ultrazyme 100G,

■ pectinase G,

■ pectinase PL,

■ hemicellulase 90,

■water-retting (preboild) and

■water-retting (normal).

メニューページへ

植物繊維の高性能化に関する研究論文

1.河原 豊, 遠藤利恵, 川下剛生, 靭皮繊維の紫外線劣化における鉄およびケラチン処理の効果, 繊維学会誌, 58(8), 314-316(2002).

2.河原 豊, 川田雄補, 遠藤利恵, 南 秀明, 西内滋典, 水熱処理によるジュート繊維の中間ラメラの崩壊, 繊維学会誌, 61, 142-145(2005).

3.河原 豊, 崎山貴之, 遠藤利恵, メタクリルアミド処理したジュート繊維の力学特性, 繊維学会誌, 61, 138-141(2005).

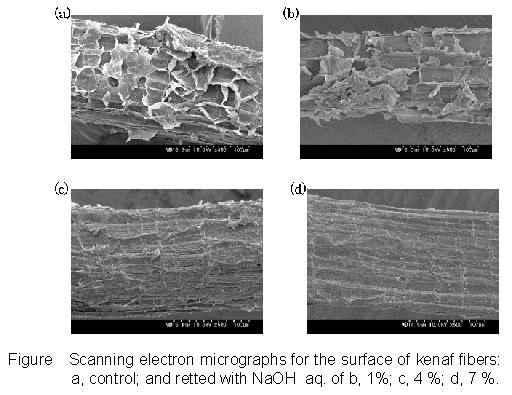

4.河原 豊, 田処圭一, 遠藤利恵, 塩谷正俊, 杉村順夫, 古澤壽治,Chemically Retted Kenaf Fibers, 繊維学会誌, 61, 115-117(2005).

5.Yutaka Kawahara, Tomoyuki Tsuda, Hideaki Minami, Shigenori Nishiuchi, and Rie Endo, Enzymatic Retting of Kudzu Fibers,

Journal of Applied Polymer Science, Vol.106, Issue 4, 2759-2762 (2007).

6.南 秀明, 西内滋典, 門野純一郎, 杉村順夫, 河原 豊, ケナフ靭皮繊維の中間ラメラへの水熱処理の影響, 繊維学会誌,65(12), 338-343(2009).

7.Akihiro Nishimura, Hisato Katayama, Yutaka Kawahara, Yukio Sugimura, Characterization of kenaf phloem fibers in relation to stem growth, Industrial Crops and Products, 37(1), 547-552 (2012).

8.Yutaka Kawahara, Yo Saito, Kiyoshi Yamamoto, Yoshimitsu Ikeda, and Yukihiro Nishikawa, Study on the Application of Kenaf Core as a Composite Reinforcement: Injection Molding of Kenaf Core/ Poly(L-lactide) Compounds. Journal of Natural Fibers, Published online: 06 Feb 2017. http://dx.doi.org/10.1080/15440478.2016.1266293

メニューページへ

s-CO2環境場のポリエステル繊維の構造変化とシシケバブ構造の存在

高速紡糸したPET繊維の粘弾性測定から示唆されるシシケバブ構造の存在

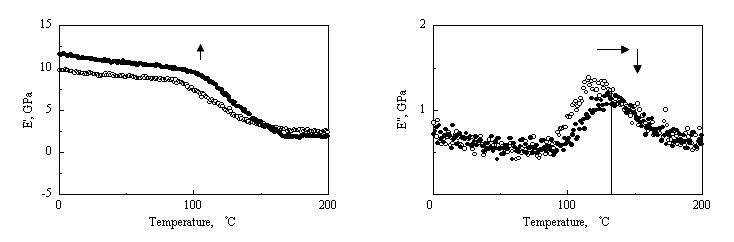

s-CO2環境場で生成する不完全な微結晶は損失弾性率を低下させピーク温度を高温側にシフトさせ分子鎖

の運動性を低下させるが、このようなs-CO2環境場での構造変化は分子鎖の緩和現象を伴うため、

通常、貯蔵弾性率が低下する。しかし、貯蔵弾性率は増加しており、これは、

積層ラメラ晶間を連結する安定なシシ骨格の存在を示唆する。

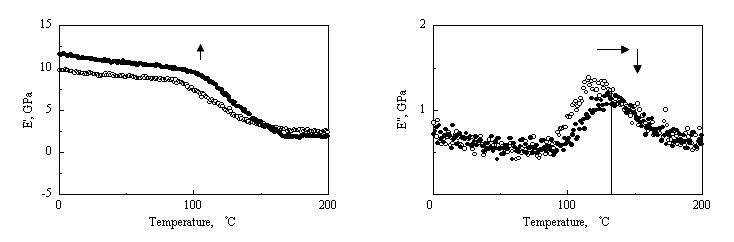

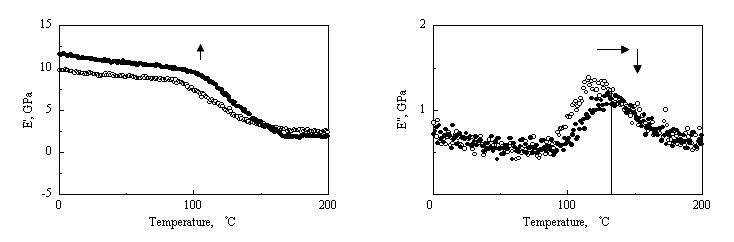

Fig.1 Temperature dependence of dynamic storage modulus E’and loss modulus E”for HSS (6km/min)

fiber: ○, control; ●, s-CO2 treared.(Kawahara, Y., Kamo, M., Yamamoto, K., Ogawa, S., Terada, D., Kikutani, T.,

Tsuji, M., Oligomer Deposition on the Surface of PET Fiber in Supercritical Carbon Dioxide Fluid,

Macromol. Mater. Eng., 291, 11-15 (2006)).

メニューページへ

PBT薄膜のTEM観察で発見されたシシケバブ構造

モデル図に示すような積層ラメラ晶を貫く細いシシ骨格の存在が確認された

Fig.2 Each of the recognized stacked-lamellar structures in uniaxially oriented thin films of

poly(butylene terephthalate) is assigned to a shish-kebab structure or a part of it

(Yoshioka T, Tsuji M, Kawahara Y, Kohjiya S, Manabe N, Yokota Y. Polymer 2005; 46:4987).

メニューページへ

ポリエステル繊維・フィルムの構造に関する研究論文

1.Yutaka Kawahara and Takeshi Kikutani, Journal of Macromolecular Science Physics, B39, 561-567(2000).

Diffusion of Organometallic Compounds into High-speed Spun Poly(ethylene terephthalate) Fiber in Supercritical

Carbon Dioxide Fluid.

2.Yutaka Kawahara, Taiyo Yoshioka, Masaki Tsuji, Masayoshi Ohara, Shinzo Kohjiya, and Takeshi Kikutani,

Journal of Macromolecular Science Physics, B39, 701-710(2000). Transmission Electron Microscopic

Investigation of the Morphology of High-Speed Spun Poly(Ethylene Terephthalate) Fibers.

3.Yutaka Kawahara, Takeshi Kikutani, and Masaki Tsuji, AATCC Review,

Influence of Interfibrillar Voids and Surface Morphology on Dyeing High-Speed Spun PET Fibers, 1(2), 34-38(2001).

4.Yutaka Kawahara, Taiyo Yoshioka, Kazuaki Sugiura, Satoshi Ogawa, and Takeshi Kikutani,

Journal of Macromolecular Science Physics, B40(2), 189-197(2001).

Dyeing Behavior of High-Speed Spun Poly(Ethylene Terephthalate) Fibers in Supercritical Carbon Dioxide.

5.河原 豊, 杉浦和明, 小川 賢, 鞠谷雄士, 繊維学会誌, 57, 220-223(2001),

超臨界二酸化炭素流体処理したポリエチレンテレフタレート繊維の構造.

6.Yutaka Kawahara, Takeshi Kikutani, Kazuaki Sugiura and Satoshi Ogawa,

Coloration Technology, 117(5), 266-269(2001). Dyeing behaviour of poly(ethylene terephthalate)

fibres in supercritical carbon dioxide.

7.Yutaka Kawahara, Taiyo Yoshioka, Masaki Tsuji, Takeshi Kikutani, Kazuaki Sugiura, and Satoshi Ogawa,

Morphology of High-speed Spun Poly(ethylene-2,6-naphthalene dicarboxylate) Fiber and its Structural Changes

by the Treatment in Supercritical Carbon Dioxide Fluid, J. Macromol.Sci.-Phys., B41(1), 177-184(2002).

8.Yutaka Kawahara, Masatoshi Shioya, and Takeshi Kikutani, Swelling Behavior of High-speed Spun Poly(ethylene

terephthalate) Fibres, J. Macromol.Sci.-Phys., B41(2), 397-406(2002).

9.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Shinzo Kohjiya, and Takeshi Kikutani,

Permanganic Etching of Poly(ethylene terephthalate) Fibers, Sen'i Gakkaishi, 58(7), 268-272(2002).

10.寺田堂彦, 河原 豊, 鞠谷雄士, 繊維学会誌, 58(9), 342-345(2002), 顕微レーザーラマン分光分析法

によるPET繊維の構造解析.

11.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Shinzo Kohjiya, Takeshi Kikutani, and Hiraku Ito,

A Study on the Fibrillar Structure Formed in Poly(ethylene naphthalate) Fibers, Ann. Rep. Res. Inst. Chem. Fib.

, Jpn., 59, 1-9(2002).

12.寺田堂彦, 河原 豊, 繊維学会誌, 59(10), 385-391(2003), 超臨界二酸化炭素流体処理によるポリエステル

新合繊の構造変化.

13.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, and Shinzo Kohjiya, Morphological study by

TEM on uniaxially oriented thin films of PET, PEN and their blends, Polymer, 44, 7997-8003(2003).

14.寺田堂彦, 河原 豊, 鞠谷雄士, 繊維学会誌, 60(12), 357-364(2004),

超臨界二酸化炭素流体処理によるポリエステル繊維の構造変化.

15.Yukiko Furuhashi, Atsushi Nakayama, Teruo Monno, Yutaka Kawahara, Hideki Yamane, Yoshiharu Kimura,

Tadahisa Iwata, X-Ray and Electron Diffraction Study of Poly(p-dioxanone), Macromol.Rapid. Commun.

, 25, 1943-1947(2004).

16.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, and Shinzo Kohjiya,

Morphological Study on Uniaxially Oriented Thin Films of Poly(butylenes terephthalate)[PBT], Ann. Rep. Res.

Inst. Chem. Fib., Jpn., 61, 33-39(2004).

17.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Takeshi Kikutani and Shinzo Kohjiya,

Internal fine structures in the high-speed-spun fibers of poly(ethylene 2,6-naphthalene dicarboxylate),

Polymer, 46, No.6, 1886-1892(2005).

18.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Takeshi Kikutani and Shinzo Kohjiya,

Internal fine structures in the high-speed-spun fibers of poly(ethylene 2,6-naphthalene dicarboxylate),

Polymer, Volume 46, Issue 14, 27 June 2005, Pages 5429-5432.

19.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Shinzo Kohjiya, Norio Manabe and Yoshimitsu Yokota,

Morphological study by TEM on uniaxially oriented thin films of PBT, Polymer, 46, No. 14, 27 June 2005,

pp. 4987-4990.

20.Yutaka Kawahara, Masaki Kamo, Kiyoshi Yamamoto, Satoshi Ogawa, Douhiko Terada, Takeshi Kikutani,

Masaki Tsuji, Oligomer Deposition on the Surface of PET Fiber in Supercritical Carbon Dioxide Fluid,

Macromol. Mater. Eng., 291, 11-15 (2006).

21.Yutaka Kawahara, Tomohiro Kurooka, Dohiko Terada, Changes in Tensile Properties for the PET Films by the Treatment in Supercritical Carbon Dioxide Fluid,

Journal of Materials Science, Volume 43, 6866-6871(2008).

22.Yutaka Kawahara, Satoshi Naruko, Atsushi Nakayama, Ming-Chien Wu, Eamor M. Woo, Masaki Tsuji, Morphological studies on single crystals and nanofibers of poly(heptamethylene terephthalate),

Journal of Materials Science, Volume 44, 4705-4709(2009).

23.Taiyo Yoshioka, Yutaka Kawahara, Takeshi Kikutani, Masaki Tsuji, Stacked-Lamellar Structure in High-Speed Spun PET Fibers as Revealed by TEM,

J. Macromol. Sci., Part B, Phys., 49, 155-162 (2010).

24.Yutaka Kawahara, Atsushi Nakayama, Masatoshi Shioya, Masaki Tsuji, Hideki Yamane, Tadahisa Iwata, Supramolecular Morphology of Two-Step, Melt-Spun Poly(dioxanone) Fibers, Journal of Materials Science, Volume 47, Issue 4 (2012), Page 1887-1892.

25.Yutaka Kawahara, Taiyo Yoshioka, Wataru Takarada, Takeshi Kikutani, and Masaki Tsuji, Alkaline Hydrolysis Kinetics of Poly(ethylene terephthalate) Fibers, Journal of Fiber Science and Technology, 72(1), 9-16 (2016).

メニューページへ

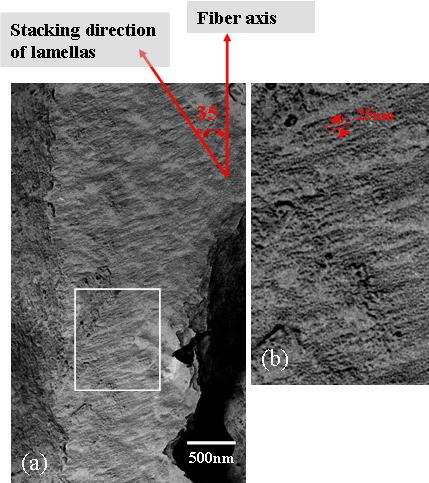

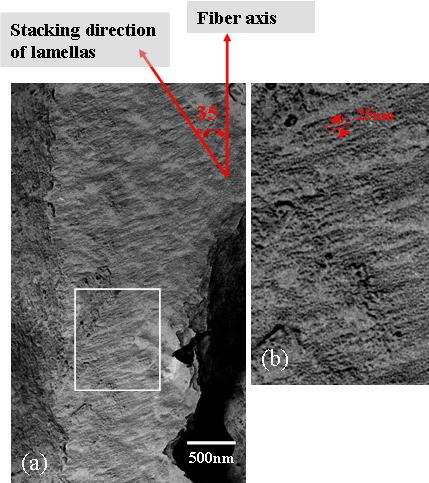

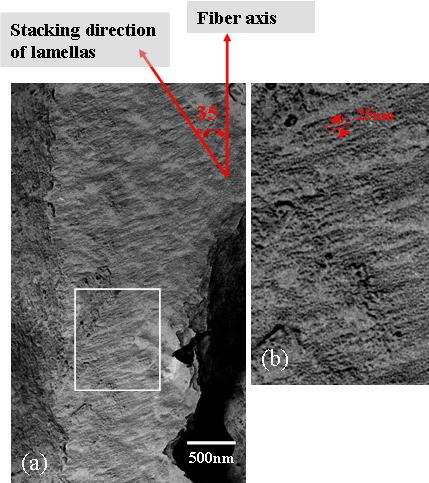

"Etached surface of HSS PET fibers"

TEM observation for high speed spun PET fibers revealed that the fiber takes stacking

lamella structure and the stacking direction is declined against fiber axis by ca. 35

degree and the long period is in the range of 10-30 nm.

These results almost coincide with the model structure proposed by Shimizu et al.

Fig. (a) Bright-field image for a replica of an etched HSS-PET fiber (spun at 6km/min).

Image (b) was enlarged with higher contrast from the white rectangular portion in image (a).

メニューページへ

5代目ハムの"くろ"です!

人生は短し、学なり難し、"くろ"の代謝速度で脳が動けば・・・・・

メニューページへ

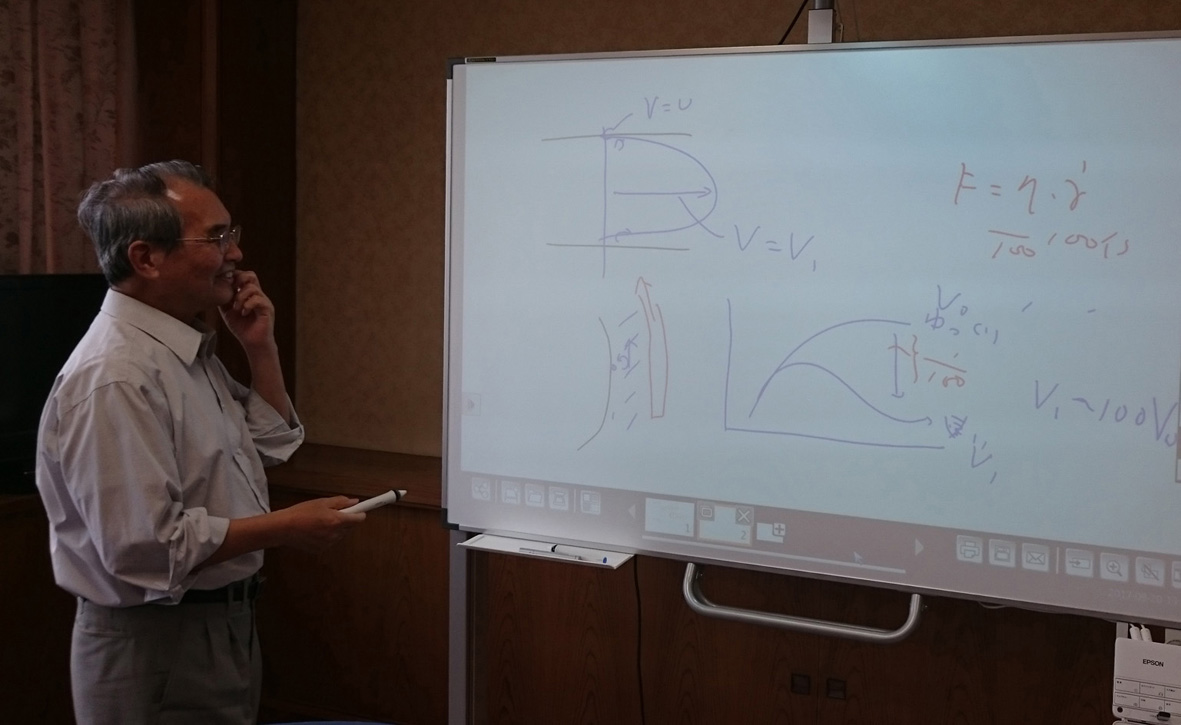

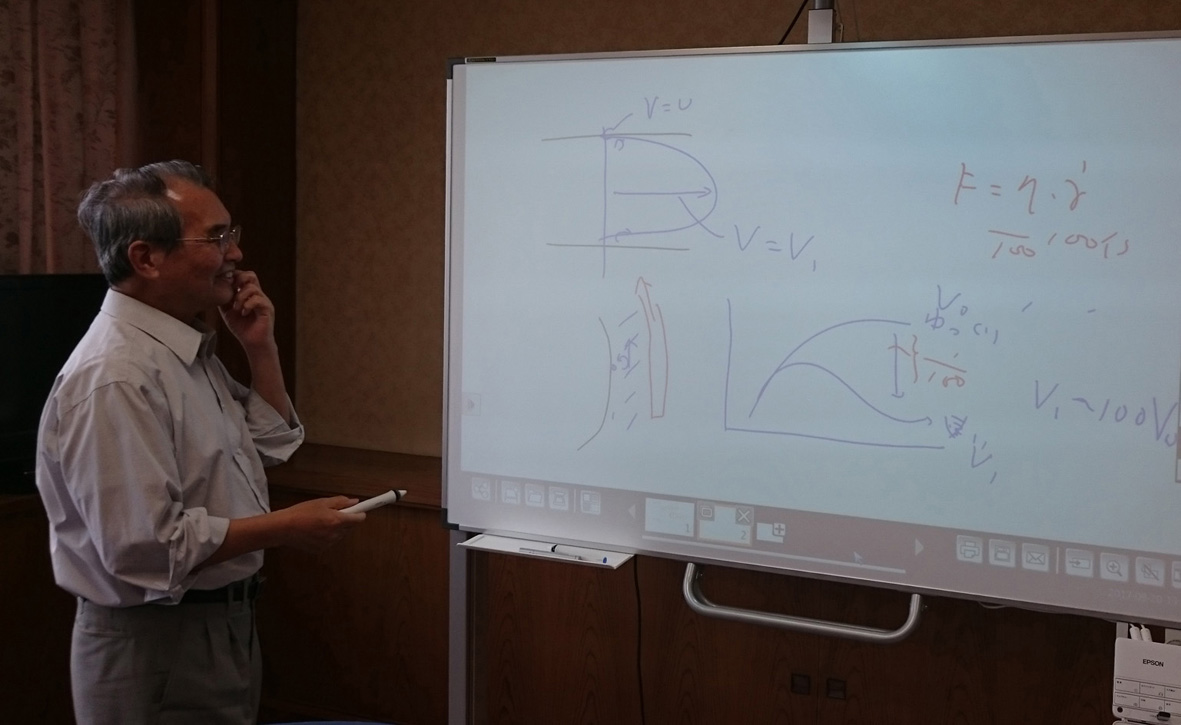

小山先生(山形大学長)からレオロジーの講義を受けました(ポリマー/フィラー界面と見かけ粘性の関係)。

先生の笑顔が深く心に残りました(2017, 9月)

楽しかったこと, OBが研究室を持ちました!父の日のうなぎの蒲焼!(2013, 6月)

メニューページへ

卒研風景(2012-13)、彼らの指先に注目!

初めてのエスカルゴの味は?

研究室風景(2011, 11月)

OB会-京都工繊大の卒業生(2011, 3月, 京都)

メニューページへ

Hessen州からBayern州を訪問(2009, 9月)

Philipps 大学マールブルグ(ドイツ)のSchaper先生!筑波山の山頂に立つ!!(2009, 3月)

Schaper先生in 横浜(2013, 4月)

メニューページへ

プサン(韓国)の大先輩とお寺を訪問(2006, 11月)

メルボルン(オーストラリア)の友人Cao先生の中庭(2005, 11月)

お久しぶりCao先生in国立博物館(上野, 2013, 5月)

メニューページへ

Welcome to KAWAHARA Lab!

GUNMA UNIVERSITY, Professor Emeritus Kawahara Laboratory

Present address

Department of Lifestyle Management, Jissen Women's University

4-1-1 Osakaue, Hino-shi, Tokyo 191-8510, JAPAN

TEL +81-42-518-9011

Email/kawahara-yutaka at jissen.ac.jp/ kawahara at gunma-u.ac.jp

When you contact, please replace "at" to "@".

(Last Update: 2025.7.13)

<IMPORTANT NOTICE!!>

Kawahara Lab. at Gunma University closed on 31th March 2025 due to the mandatory age-limit retirement.

I would like to give thanks for your interests and good supports.

However, on April 1st, 2025, my private laboratory standing near Nagatsuta station in Midori-ku Yokohama city

has been opened. Please visit my “Kawahara Technology Research Laboratory”.

My Gunma University E-mail address is still available after my retirement.

Also, prof. Kawahara is now belonging to Jissen Women's University in Hino campus

and has opened the laboratory. Please contact if you need.

Video Report

Experiments on the Forcibly Spinning of Bombyx mori silkworm!

Recent Reports

“Possible relationships between the physical conditions of cattle

and the occurrence of structural modifications of their coat hair”

“Comprehensive Study on the Formation of Higher-Order Structure of

Bombyx mori Silkworm Fibers: Influence of Sericin Fractions,

Modulation of Spinning Process, and Metal Ion Interactions”

“Recrystallization Behavior and Mechanical, and

Carbonizing Properties of Feather Keratin Resin

Sheets Produced by Hot-Compression Molding”

Past Projests

Coffee break

(Please click the underlined terms)

Introduction to Biomass Science

Biomass is a keyword for the sustainability society.

Silk has been used as a textile material in our daily life and silk

garments sometimes represent culture and status for human beings.

Nowadays, additional functional properties have been found out for

silk from the viewpoints of food industry, cosmetic material, medical use etc.

It is nothing but silk is a reproducible material.

When we consider the construction of bio-production system,

silk is a very promising material.

Also, it is essential for the sustainability society to expand industrial use of vegetable fibers.

However, physical and chemical natures of vegetable fiber have not been fully established so far.

Frontier works are needed for opening this potential research field,

which definitely contributes to global sustainability.

CV of Prof. Kawahara

1.Education: Tokyo Institute of Technology, 1983 BA., 1985 MS., 1996, Dr. Eng.

2.Personal history:

1985-Researcher, NKK CORPORATION

1988-Researcher, Tokyo Metropolitan Textile Research Institute

1998-Associate Professor, Kyoto Institute of Technology

2006-Professor, Gunma University

2025-Professor Emeritus, Gunma University

2025-Professor, Jissen Women's University (present affiliation)

3.Awards:

(1) Paper prize of the Japan Society of Polymer Processing, 1991.

(2) Paper prize of the Society of Fiber Science and Technology Japan, 1994.

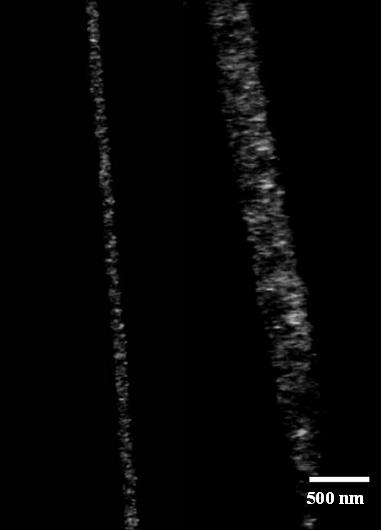

Electrospinning of Biodegradable Nanofibers

Structural Study on Electrospun Nanofibers of Polydioxanone

Nanofibers of polydioxanone (PPDX) were electrospun from 3.0-wt% solution in

1,1,1,3,3,3-hexafluoro-2-propanol. Structure and morphology of the electrospun

nanofibers were investigated by transmission electron microscopy (TEM).

In order to align and collect nanofibers parallel to each other, we used

a homemade collector with separated electrodes which was specially designed.

TEM revealed that thus aligned nanofibers on the collector are partially crystallized.

The SAED patterns of nanofibers, which were drawn and/or heat-treated with

being deposited on the collector, showed a well-developed fiber pattern.

In the dark-field image of heat-treated nanofibers, many striations which are

running perpendicular to the fiber axis were observed. These striations appear

to be a part of stacked-lamellar structure oriented in the direction of fiber axis.

This result indicated that heat-treated PPDX nanofibers have stacked-lamellar structure.

Fig.1 Dark-field image of the heat-treated electrospun PPDX nanofibers by using the 210 and 020 reflections.

Go to project index page

Articles Published

1.Atsushi Nakayama, Yutaka Kawahara, Yoshitaka Hayakawa, Ryosuke Takahashi, Taiyo Yoshioka, and Masaki Tsuji, Sen'i Gakkaishi, 63, 230-234(2007),

Structural study on electrospun nanofibers of polydioxanone.

2.Yutaka Kawahara, Atsushi Nakayama, Noriaki Matsumura, Taiyo Yoshioka and Masaki Tsuji,

Structure for Electro-spun Silk Fibroin Nanofibers,

Journal of Applied Polymer Science, Volume107, 3681-3684(2008).

3.Yutaka Kawahara, Satoshi Naruko, Atsushi Nakayama, Ming-Chien Wu, Eamor M. Woo, Masaki Tsuji, Stacked-lamellar Structure of Electrospun Poly(heptamethylene terephthalate) Nanofibers,

Journal of Materials Science, 44, 2137-2142(2009).

4.Taiyo Yoshioka, Yutaka Kawahara, Masaki Tsuji, Andreas K. Schaper, Structural Modification of PVA Nanofibers by Water Vapor Annealing, Sen’I Gakkaishi, 67(6), 138-140 (2011).

5.Yoshioka, Taiyo; Kawahara, Yutaka; Schaper, Andreas, Cyclic or permanent ? Structure control of the contraction behavior of regenerated Bombyx mori silk nanofibers, Macromolecules, 44, 7713-7718(2011).

6.Andreas K. Schaper, Taiyo Yoshioka, Yutaka Kawahara, Fascinating Silk-- Electrospinning, Contraction and Diffraction Experiments, G.I.T. Imaging & Microscopy, Volume 14, Issue 2, 25-27 (2012).

Go to project index page

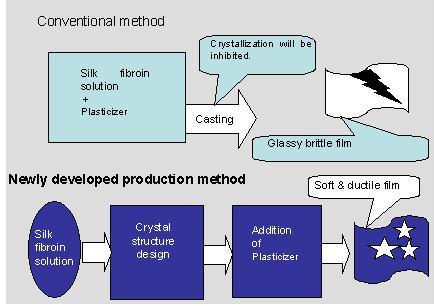

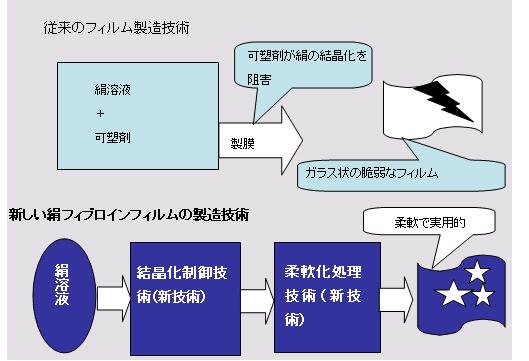

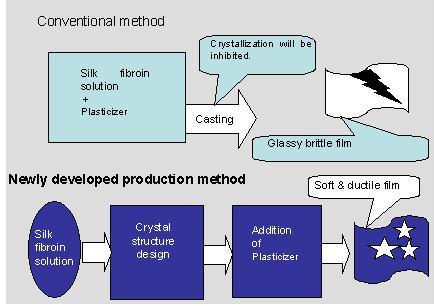

Ductile Soft Silk Fibroin Films

Abstract

Silk fibroin cast film was prepared using a ternary solvent system of CaCl2/CH3CH2OH/H2O (1/2/8 in mole ratio).

A drying temperature at casting influenced crystal structure of fibroin. When a drying

temperature was set lower than 9 centigrade, the cast film became amorphous.

When a drying temperature was set higher than 40 centigrade, a fibroin

film of silk-II structure was obtained. In order to produce a fibroin film of

silk-I structure, a preferable temperature range was from 20 to 26 centigrade.

The crystal transformation from random coil structure into

silk-I could be made through exposure of an amorphous film to water vapor.

As for the crystal transformation from silk-I into silk-II, the treatment

with a glycerin solution was effective. In the course of

the treatment a film showed self-thinning and self-expanding.

The expansion ratio exceeded 40 % at maximum.

The film produced accompanying self-expansion was ductile in nature.

Fig.1 Newly developed technology for the production of soft ductile silk fibroin films.

Go to project index page

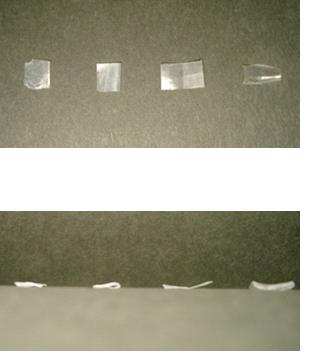

←Fig.2 Comparison in ductility between developed silk fibroin

←Fig.2 Comparison in ductility between developed silk fibroin

film (left side) and conventional ones.

Go to project index page

Articles Published

1.Yutaka Kawahara, Keiko Furukawa, Takeshi Yamamoto, Self-Expansion Behavior of Silk Fibroin Film,

Macromol. Mater. Eng., 291, 458-462 (2006).

2.Yutaka Kawahara, Keiko Furukawa, Takeshi Yamamoto, Miwa Masuda, Tsutomu Furuzono, Development of Soft Silk Fibroin Film,

Nippon Silk Gakkaishi, 15, 3-6(2006).

3.Yutaka Kawahara, Akira Ito, Separation of Ethanol-Water Mixtures by the Membranes Prepared from Liquid Silk, Sen'i Gakkaishi,70(2), 23-27 (2014).

Development of a Biodegradable Film and Fiber Using Paramylon Prepared from Euglena Gracilis

Abstract

The Euglena family is classified in both vegetable and single cellular animal,

a monad that can move with its tail using like a screw and synthesizes paramylon as storage polysaccharide

from CO2 and solar energy. The polysaccharide consists of triple helical structure of (1→3)-β-D-glucans

and has crystallinity over than 90 % though the degree of polymerization (DP) is no more than 700.

Such specific properties of paramylon, that is, high crystallinity and low DP are unwelcome from a viewpoint

of polymer processing. The wet process was applied to paramylon to produce stable films and fibers.

Formic acid was suitable for the preparation of a solution of paramylon,

and a transparent even yellow film was obtained by casting the solution on a glass plate

and drying the cast film in air without using coagulation bath.

The tensile strength of the regenerated film was enhanced by the treatment using hot pressurized water.

The spinability of a paramylon solution was a little enhanced by blending polyvinyl alcohol

(PVA) up to 70 %. The paramylon / PVA blend fibers were produced through

wet spinning using coagulation bath of conc. Na2SO4 at a room temperature.

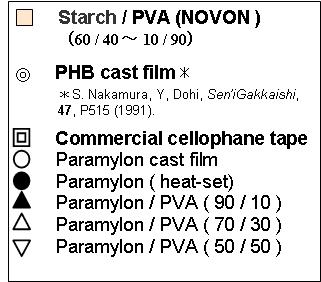

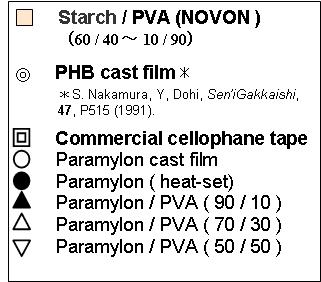

Fig.1 Tensile strength of regenerated films prepared using paramylon from Euglena Gracilis.

Go to project index page

Fig.2 Aspect of regenerated film.

Fig.3 Aspect of regenerated blend fibers.

Go to project index page

Articles Published

1.Yutaka Kawahara, Akihiro Koganemaru, Development of Novel Film Using Paramylon Prepared from Euglena Gracilis,

Journal of Applied Polymer Science, Vol.102, pp.3495-3497(2006).

2. Yutaka Kawahara, (1→3)- β-D-Glucan nanofibers from paramylon via electrospinning,

Carbohydrate Polymers, Vol. 112, pp. 73-76 (2014).

Go to project index page

Production of Functional Carbons from Biomass

Aims

Pitches and cokes, the heavy fractions of petroleum and coal,

are two major starting materials of various carbons such as carbon blacks,

carbon fibers and activated carbons. Their carbonization behavior

and the properties of the resulting carbons have been studied extensively.

In contrast, very little attention has been paid to the carbonization behavior of natural resources.

Pore Size Distribution of Activated Carbons from Bamboos

The potassium fractions will accelerate the gas reaction in activation process,

which affects the utilization of the cellular structure of vegetable.

Fig.1 Influence of Potassium on TG curves of carbonized bamboos.

Go to project index page

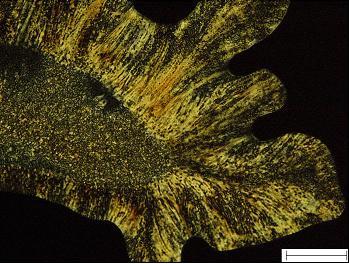

The degree of graphitization of L-tryptophan is nearly equal to

the carbons from acenaphthylene.

Carbonization behavior of L-tryptophan has been investigated.

The carbon derived from L-tryptophan by the heat-treatment at 3000 centigrade

showed almost the same degree of graphitization as that from acenaphthylene and

the average interlayer spacings of both these carbons approached to 0.3354 nm.

The ratio, R, of the intensity of the Raman band at 1360 cm-1 against that at

1580 cm-1 and the half width, Dl, of the Raman band at 1580 cm-1 were measured.

The R and Dl are the measures for the degree of graphitization.

Those values for the carbon from L-tryptophan were nearly equal to those for

the carbon from acenaphthylene.

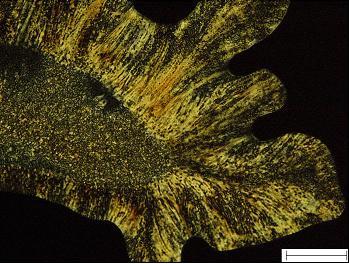

Fig.2 Polarizing transmitted light micrographs of thin film of

L-tryptophan heat-treated at 500 oC for 2h representing anisotropic

flow-type texture of mesophase. Scale bars correspond to 50 μm.

Go to project index page

Articles Published

1.Yutaka Kawahara, Goro Nishikawa, Hiroaki Kanai, Hisayuki Takigawa, Sen'i Gakkaishi, 57, 298-300(2001), Carbonization Behavior of Water Plants, Elodea Nuttallii, and Utility of Carbonized Materials.

2.Goro Nishikawa, Yutaka Kawahara, Sen'i Gakkaishi, 59(5), 163-167(2003), Carbonization Behavior of Wheat Bran and Utility of their Carbonized Products.

3.Goro Nishikawa, Yutaka Kawahara, Masatoshi Shioya, Sen'i Gakkaishi, 60(4), 105-111(2004), Carbonization Behavior of Silk.

4.Hiroyuki Wakisaka, Hajime Miyake, Yutaka Kawahara, Preparation of activated carbon from beer lees and influence of protein fraction on activation process, TANSO, No.218, 192-196 (2005).

5.Yutaka Kawahara, Masayoshi Izumoto, Goro Nishikawa, Hiroyuki Wakisaka, Norio Iwashita, Kazuyoshi Yamamoto, Noboru Ishibashi, Carbonization Behavior of Reed Grass and Production of Activated Carbon, Sen'i Gakkaishi, 62(10), 242-244(2006).

6.Goro Nishikawa, Masatoshi Shioya, Norio Iwashita and Yutaka Kawahara, Carbonization behavior of L-tryptophan and gluten, Journal of Materials Science, 42(6), 2076-2080(2007).

7.Yutaka Kawahara, Kazuyoshi Yamamoto, Hiroyuki Wakisaka, Kaori Izutsu, Masatoshi Shioya, Toshiaki Sakai, Yutaka Takahara, Noboru Ishibashi, Carbonaceous adsorbents produced from coffee lees,

Journal of Materials Science, Volume 44, 1137-39(2009).

8.Kazuyoshi Yamamoto, Yutaka Kawahara, Masatoshi Shioya, Noboru Ishibashi, Utilization of triacetylcellulose waste for the production of carbonaceous adsorbents, Journal of Polymers and the Environment, 20(2), 626-630 (2012).

9.Noboru Ishibashi, Kazuyoshi Yamamoto,Hiroyuki Wakisaka, Yutaka Kawahara, Influence of the hydrothermal pre-treatments on the adsorption characteristics of activated carbons from woods, Journal of Polymers and the Environment, 22(2), 267-271(2014).

Go to project index page

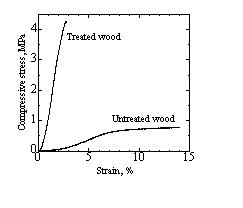

Shrinkproof and Reinforcing Effects of Duck Feather Keratin Hydrolysate on the Conservation Treatment of Archaeological Waterlogged Wood

Abstract

Shrinkproof and reinforcing effects of duck feather keratin hydrolysate on the conservation treatment of

archaeological waterlogged wood were investigated. The bulking effect, i.e. the shrink proof index was enhanced

through the impregnation of cell walls with duck feather hydrolysate and sodium acetate derived

from neytralization process in the preparation of pH 7 duck feather hydrolysate solution.

The reinforcement of cell walls seems to be brought about through the structural modification of duck feather

hydrolysate to beta sheet form by acetic acid in the treatment bath. The good affinity between lignin, main

component of biodegraded waterlogged wood, and duck feather keratin is also effective for the reinforcement

of cell walls. In addition, this treatment is effective for the protection of treated wood against UV rays.

The reinforcement effect of keratin hydrolysate is promising for certain kinds of vegetable fibers.

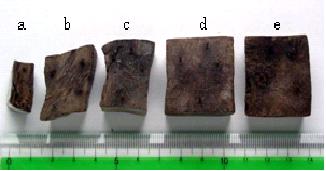

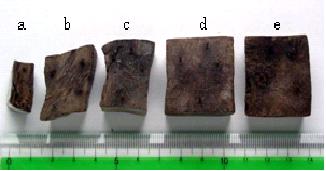

Shrinkproof Effect

The treted wood(right→) retained its shape whereas the large shrinkage was observed for untreated wood(←left).

Fig.1 Appearance of archaeological waterlogged wood specimens dried:

a, untreated, and the specimens treated with duck feather solutions

of b, 10%, c, 20%, d, 30% and e, 40%.

Go to project index page

Reinforcing Effect

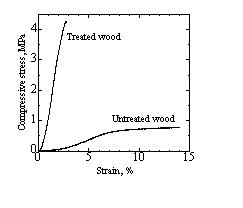

←Fig.2 Compressive stress-strain curves of arhcaeological waterlogged wood specimens.

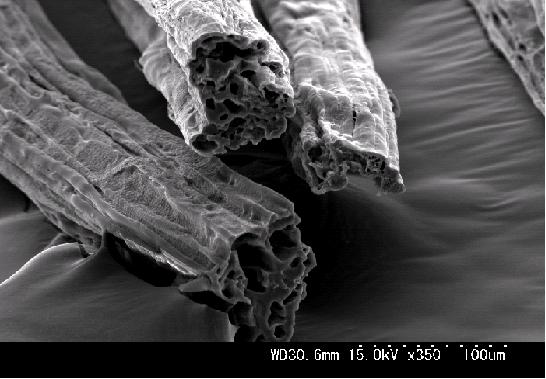

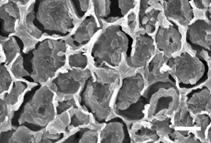

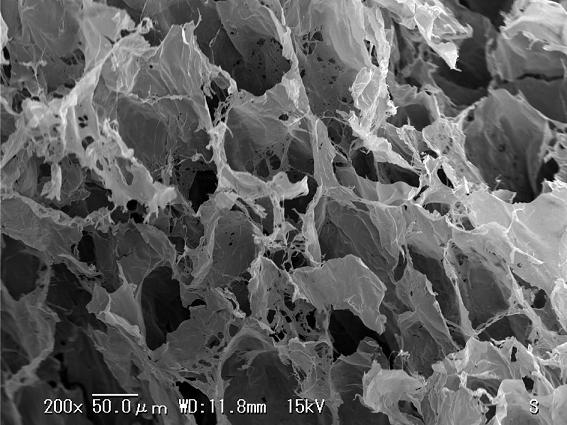

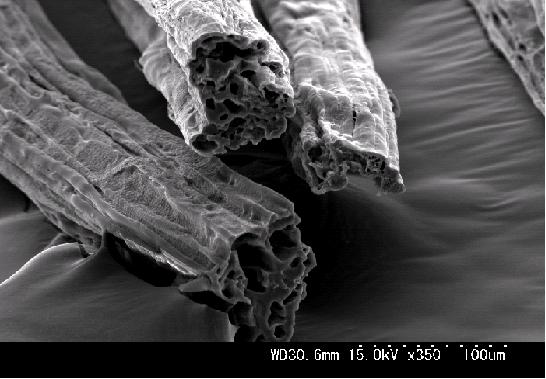

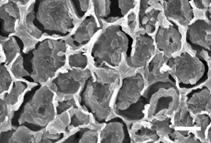

→Fig.3 Scanning electron micrograph of the cross-section for archaeological waterlogged wood

specimens treated with duck feather hydrolysate. Scale bar = 10μm.

Biodegraded cell walls of archaeological waterlogged wood are directly reinforced by the keratin hydrolysate

because we can distinguish space between cell walls and settled chemicals. It is not merely based on

the impregnation mechanism.

Visit to National Museum of Denmark

7th September 2007

Go to project index page

Articles Published

1.Rie Endo, Yutaka Kawahara, Shrinkproof and Reinforcing Effects of Duck Feather Hydrolysate on the Treatment of Archaeological Waterlogged Wood, Sen'i Gakkaishi, 60, 372-376(2004).

2.Rie Endo, Yutaka Kawahara, Kaeko Kamei, Conservation Finishing for Archaeological Waterlogged Wood Using Feather Hydrolysate, Sen'i Gakkaishi, 60, 125-129(2004).

3.Yutaka Kawahara and Rie Endo, Chemical Finishing of Bast Fibers and Woods Using Hydrolyzed Keratin from Waste Wool or Down, Textile Research Journal, 74(2), 93-96 (2004).

4.Rie Endo, Kaeko Kamei, Ikuho Iida and Yutaka Kawahara, Dimensional stability of waterlogged wood treated with hydrolyzed feather keratin,

Journal of Archaeological Science, Volume 35, 240-1246(2008).

Go to project index page

New Vegetable Fibers

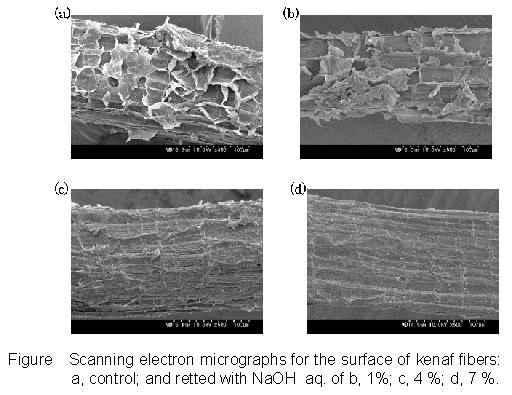

Retting Technology

The vegetable fibers should be used more widely in the industrial fields.

European and Japanese motor companies use the plastics reinforced by vegetable

fibers for the interior parts. To retain the mechanical properties of vegetable fibers,

the retting is the most important and critical process. The figures show the surface of

retted fibers. To elevate the smoothness of fibers, the concentration of alkali in retting bath

must be controlled over than 4%. However, the mechanical properties tend to be affected

by the attack of alkali to the middle lamella between the fibrous cells constructing the fiber.

Go to project index page

Aesthetic Luster

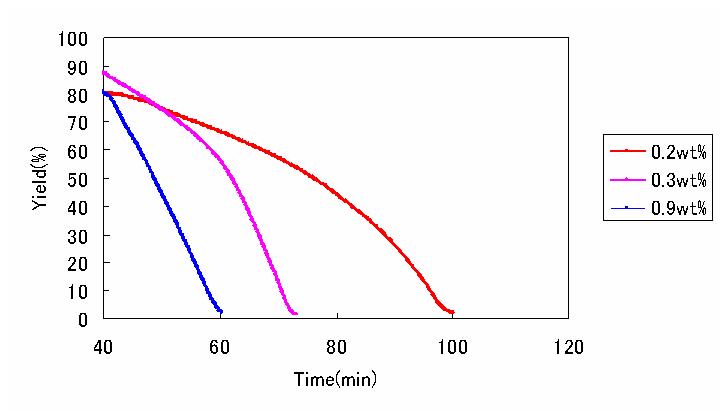

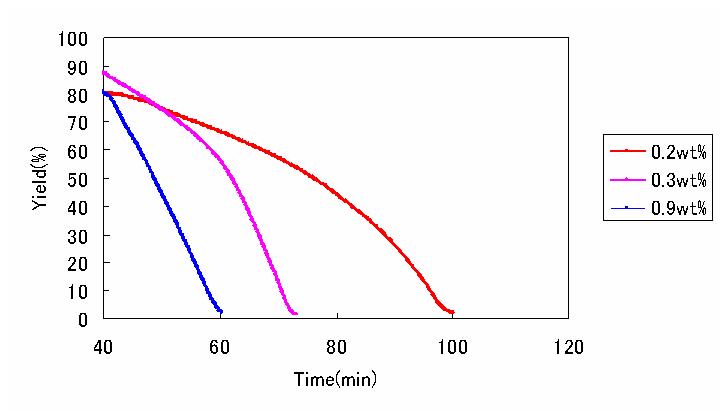

The enzymatic retting of kudzu fibers were performed using several commercial

enzymes and the effects on the retting were compared from the viewpoints of

the smoothness for the surface of fibers as well as mechanical properties.

The commercial enzymes used could be classified into two types,

i.e. cellulase-type and pectinase-type. For cellulase-type, the enzymatic

decomposition occurred almost topochemically because of the cooperation of

the cellulase with high activity and the retting was fully achieved suppressing

the damage to the intercellular matrix (middle lamella) by pectinase.

For pectinase-type, the decomposition predominately

occurred in the middle lamella that joints the adjacent fibrous cells.

Therefore the tensile properties of retted fibers were fairly lowered.

In the retting of kudzu fibers, a topochemical process is promising

to produce the fibers with excellent luster retaining tensile properties.

Relative luster of kudzu fibers retted with enzymes.

Incident beam angle was set at 15°from horizontal and

regular reflection was measured along to the fiber axis.

■viscozyme L,

■ ultrazyme 100G,

■ pectinase G,

■ pectinase PL,

■ hemicellulase 90,

■ traditionalwater-retting (preboild) and

■ traditionalwater-retting (normal).

Go to project index page

Articles Published

1.Yutaka Kawahara, Rie Endo, Goki Kawashita, Influence of Ferrous Contaminations or Keratin Treatments on the Degradation of Bast Fibers by Irradiation with Ultraviolet Rays, Sen'i Gakkaishi, 58(8), 314-316(2002).

2.Yutaka Kawahara, Yusuke Kawata, Rie Endo, Hideaki Minami, Shigenori Nishiuchi, Destruction of Middle Lamella in Jute Fibers by Hydrothermal Treatment, Sen'i Gakkaishi, 61, 142-145(2005).

3.Yutaka Kawahara, Takayuki Sakiyama, Rie Endo, Tensile Properties for Jute Fibers Treated with Methacrylamide, Sen'i Gakkaishi, 61, 138-141(2005).

4.Yutaka Kawahara, Keiichi Tadokoro, Rie Endo, Masatoshi Shioya, Yukio Sugimura, Toshiharu Furusawa, Chemically Retted Kenaf Fibers, Sen'i Gakkaishi, 61, 115-117(2005).

5.Yutaka Kawahara, Tomoyuki Tsuda, Hideaki Minami, Shigenori Nishiuchi, and Rie Endo, Enzymatic Retting of Kudzu Fibers,

Journal of Applied Polymer Science, Vol.106, Issue 4, 2759-2762 (2007).

6.Akihiro Nishimura, Hisato Katayama, Yutaka Kawahara, Yukio Sugimura, Characterization of kenaf phloem fibers in relation to stem growth, Industrial Crops and Products, 37(1), 547-552 (2012).

Go to project index page

Viscoelastic Changes through s-CO2 Treatments and Shish Kebab Structure Observed for Polyester

Peculiar Viscoelastic Changes for the High-speed-spun PET Fibers Measured after s-CO2 Treatment

The peak intensity of loss modulus was a little weakened and the position was shifted to the higher

temperature side. Such viscoelastic changes is due to binding of amorphous chains by the imperfect

small crystallites generated in amorphous regions.

Shish kebab structure propagated the stabilizing effects of amorphous chains by the imperfect

small crystallites generated in amorphous regions along the fiber axis. Then,

the storage modulus increased.

Fig.1 Temperature dependence of dynamic storage modulus E’and loss modulus E”for HSS (6km/min)

fiber: ○, control; ●, s-CO2 treared.(Kawahara, Y., Kamo, M., Yamamoto, K., Ogawa, S., Terada, D., Kikutani, T.,

Tsuji, M., Oligomer Deposition on the Surface of PET Fiber in Supercritical Carbon Dioxide Fluid,

Macromol. Mater. Eng., 291, 11-15 (2006)).

Go to project index page

Shish-kebab Structure in an Uniaxially Oriented PBT Thin Film

Fig.2 Each of the recognized stacked-lamellar structures in uniaxially oriented thin films of

poly(butylene terephthalate) is assigned to a shish-kebab structure or a part of it

(Yoshioka T, Tsuji M, Kawahara Y, Kohjiya S, Manabe N, Yokota Y. Polymer 2005; 46:4987).

Go to project index page

Articles Published

1.Yutaka Kawahara and Takeshi Kikutani, Journal of Macromolecular Science Physics, B39, 561-567(2000).

Diffusion of Organometallic Compounds into High-speed Spun Poly(ethylene terephthalate) Fiber in Supercritical

Carbon Dioxide Fluid.

2.Yutaka Kawahara, Taiyo Yoshioka, Masaki Tsuji, Masayoshi Ohara, Shinzo Kohjiya, and Takeshi Kikutani,

Journal of Macromolecular Science Physics, B39, 701-710(2000). Transmission Electron Microscopic

Investigation of the Morphology of High-Speed Spun Poly(Ethylene Terephthalate) Fibers.

3.Yutaka Kawahara, Takeshi Kikutani, and Masaki Tsuji, AATCC Review,

Influence of Interfibrillar Voids and Surface Morphology on Dyeing High-Speed Spun PET Fibers, 1(2), 34-38(2001).

4.Yutaka Kawahara, Taiyo Yoshioka, Kazuaki Sugiura, Satoshi Ogawa, and Takeshi Kikutani,

Journal of Macromolecular Science Physics, B40(2), 189-197(2001).

Dyeing Behavior of High-Speed Spun Poly(Ethylene Terephthalate) Fibers in Supercritical Carbon Dioxide.

5.Yutaka Kawahara, Kazuaki Sugiura, Satoshi Ogawa, Takeshi Kikutani, Sen'i Gakkaishi, 57, 220-223(2001),

Structure of Poly(ethylene terephthalate) Fibers Treated in Supercritical Carbon Dioxide Fluid.

6.Yutaka Kawahara, Takeshi Kikutani, Kazuaki Sugiura and Satoshi Ogawa,

Coloration Technology, 117(5), 266-269(2001). Dyeing behaviour of poly(ethylene terephthalate)

fibres in supercritical carbon dioxide.

7.Yutaka Kawahara, Taiyo Yoshioka, Masaki Tsuji, Takeshi Kikutani, Kazuaki Sugiura, and Satoshi Ogawa,

Morphology of High-speed Spun Poly(ethylene-2,6-naphthalene dicarboxylate) Fiber and its Structural Changes

by the Treatment in Supercritical Carbon Dioxide Fluid, J. Macromol.Sci.-Phys., B41(1), 177-184(2002).

8.Yutaka Kawahara, Masatoshi Shioya, and Takeshi Kikutani, Swelling Behavior of High-speed Spun Poly(ethylene

terephthalate) Fibres, J. Macromol.Sci.-Phys., B41(2), 397-406(2002).

9.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Shinzo Kohjiya, and Takeshi Kikutani,

Permanganic Etching of Poly(ethylene terephthalate) Fibers, Sen'i Gakkaishi, 58(7), 268-272(2002).

10.Douhiko Terada, Yutaka Kawahara, Takeshi Kikutani, Sen'i Gakkaishi, 58(9), 342-345(2002), Structural Analysis for PET Fiber using Laser Raman Microprobe Spectroscopy.

11.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Shinzo Kohjiya, Takeshi Kikutani, and Hiraku Ito,

A Study on the Fibrillar Structure Formed in Poly(ethylene naphthalate) Fibers, Ann. Rep. Res. Inst. Chem. Fib.

, Jpn., 59, 1-9(2002).

12.Douhiko Terada, Yutaka Kawahara, Sen'i Gakkaishi, 59(10), 385-391(2003), Structural Modification of Polyester Shin-Gosen by the Treatment in Supercritical Carbon Dioxide Fluids.

13.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, and Shinzo Kohjiya, Morphological study by

TEM on uniaxially oriented thin films of PET, PEN and their blends, Polymer, 44, 7997-8003(2003).

14.Douhiko Terada, Yutaka Kawahara, Takeshi Kikutani, Sen'i Gakkaishi, 60(12), 357-364(2004),

Structura Modification of Polyester Fibers in Supercritical Carbon Dioxide Fluid.

15.Yukiko Furuhashi, Atsushi Nakayama, Teruo Monno, Yutaka Kawahara, Hideki Yamane, Yoshiharu Kimura,

Tadahisa Iwata, X-Ray and Electron Diffraction Study of Poly(p-dioxanone), Macromol.Rapid. Commun.

, 25, 1943-1947(2004).

16.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, and Shinzo Kohjiya,

Morphological Study on Uniaxially Oriented Thin Films of Poly(butylenes terephthalate)[PBT], Ann. Rep. Res.

Inst. Chem. Fib., Jpn., 61, 33-39(2004).

17.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Takeshi Kikutani and Shinzo Kohjiya,

Internal fine structures in the high-speed-spun fibers of poly(ethylene 2,6-naphthalene dicarboxylate),

Polymer, 46, No.6, 1886-1892(2005).

18.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Takeshi Kikutani and Shinzo Kohjiya,

Internal fine structures in the high-speed-spun fibers of poly(ethylene 2,6-naphthalene dicarboxylate),

Polymer, Volume 46, Issue 14, 27 June 2005, Pages 5429-5432.

19.Taiyo Yoshioka, Masaki Tsuji, Yutaka Kawahara, Shinzo Kohjiya, Norio Manabe and Yoshimitsu Yokota,

Morphological study by TEM on uniaxially oriented thin films of PBT, Polymer, 46, No. 14, 27 June 2005,

pp. 4987-4990.

20.Yutaka Kawahara, Masaki Kamo, Kiyoshi Yamamoto, Satoshi Ogawa, Douhiko Terada, Takeshi Kikutani,

Masaki Tsuji, Oligomer Deposition on the Surface of PET Fiber in Supercritical Carbon Dioxide Fluid,

Macromol. Mater. Eng., 291, 11-15 (2006).

21.Yutaka Kawahara, Tomohiro Kurooka, Dohiko Terada, Changes in Tensile Properties for the PET Films by the Treatment in Supercritical Carbon Dioxide Fluid,

Journal of Materials Science, Volume 43, 6866-6871(2008).

22.Yutaka Kawahara, Satoshi Naruko, Atsushi Nakayama, Ming-Chien Wu, Eamor M. Woo, Masaki Tsuji, Morphological studies on single crystals and nanofibers of poly(heptamethylene terephthalate),

Journal of Materials Science, Volume 44, 4705-4709(2009).

23.Taiyo Yoshioka, Yutaka Kawahara, Takeshi Kikutani, Masaki Tsuji, Stacked-Lamellar Structure in High-Speed Spun PET Fibers as Revealed by TEM,

J. Macromol. Sci., Part B, Phys., 49, 155-162 (2010).

24.Yutaka Kawahara, Atsushi Nakayama, Masatoshi Shioya, Masaki Tsuji, Hideki Yamane, Tadahisa Iwata, Supramolecular Morphology of Two-Step, Melt-Spun Poly(dioxanone) Fibers, Journal of Materials Science, Volume 47, Issue 4 (2012), Page 1887-1892.

Go to project index page

"Etached surface of HSS PET fibers"

TEM observation for high speed spun PET fibers revealed that the fiber takes stacking

lamella structure and the stacking direction is declined against fiber axis by ca. 35

degree and the long period is in the range of 10-30 nm.

These results almost coincide with the model structure proposed by Shimizu et al.

Fig. (a) Bright-field image for a replica of an etched HSS-PET fiber (spun at 6km/min).

Image (b) was enlarged with higher contrast from the white rectangular portion in image (a).

Go to project index page

Hello! My name is "KURO-5!"

Go to project index page

Party in lab. (Nov., 2011)

OB meeting with my graduate students from Kyoto Institute of Tech. (Mar., 2011 in Kyoto)

Philipps University, Marburg, Germany,

Dr. A. Schaper on the top of Mt. TSUKUBA!(Mar., 2009)

Mr.& Mrs.Schaper in Yokohama(Apr., 2013)

Visiting an old Korean temple with my friend in Busan(Nov.,2006)

My friend’s garden in Melbourne, Australia(Nov., 2005)

Welcome to Japan! Dr. Cao (National Museum in Ueno, May, 2013)

Go to project index page

←Fig.2 Comparison in ductility between developed silk fibroin

←Fig.2 Comparison in ductility between developed silk fibroin